Common water wave stamped stainless steel sheets are made of 304 steel, 304L steel. Some areas with special requirements will also use 316 steel with better corrosion resistance. Produced by different factories, the specifications and sizes are slightly different. The general width is 0.5m, 0.8m, 1m, 1.22m, 1.5m, and the length can be customized. Colors can also be customized, such as natural, bronze, champagne, blue, etc.

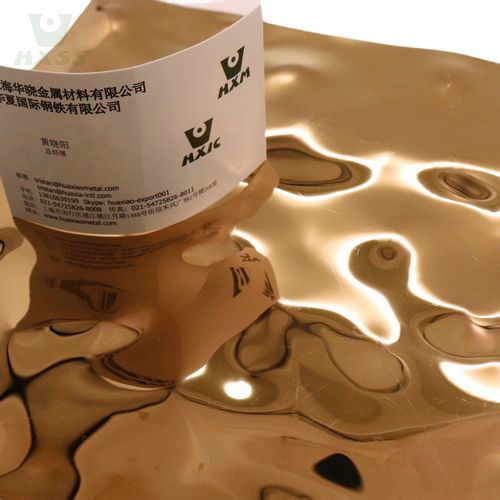

Water Wave Stamped Stainless Steel Sheets

About Huaxiao Water Wave Stamped Stainless Steel Sheets Supplier | Manufacturer

Huaxiao develops its own proprietary technology as needed to realize the design intent of the following custom mirror polished water-corrugated stainless steel examples.

In recent years, Huaxiao has observed an upward trend in the use of water ripple (embossed) mirror polished stainless steel. To this end, Huaxiao designed a method that allows us to emboss high-quality mirror-polished stainless steel in selected areas of selected areas without causing any damage or scratches.

Specification and size of Water Wave Stamped Stainless Steel Sheets

Common water wave stamped stainless steel sheets are made of 304 steel, and 304L steel. Some areas with special requirements will also use 316 steel with better corrosion resistance. Produced by different factories, the specifications and sizes are slightly different The general width is 0.5m, 0.8m, 1m, 1.22m, and 1.5m, and the length can be customized. Colors can also be customized, such as natural, bronze, champagne, blue, etc. More natural colors in regular use.

Water wave stamped stainless steel sheets

Water ripple stainless steel sheets can be customized with various patterns. Common ones are pearl rice, pearl board, refined corrugated board, Dozens of small squares, diamond-shaped squares, antique squares, leather patterns, etc.

| Type | Water wave stamped stainless steel sheets/water ripple stainless steel sheets |

|---|---|

| Color | silver, gold, rose gold, champagne, copper, black, blue, etc. |

| Thickness | 0.3 mm – 3.0 mm, etc. |

| Size | 1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max.width 1500mm |

| SS Grade | 304,316, 201,430 etc. |

| Finish | PVD Color + Stamped +Mirror |

| Avaible finishes | No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination, etc. |

| Steel Mill | POSCO,JISCO,TISCO,LISCO,BAOSTEEL, etc. |

| Packing way | PVC+ waterproof paper + strong sea-worthy wooden package, etc. The packaging method can be adjusted according to customer requirements. |

Chemical Composition

| Grade | STS304 | STS 316 | STS430 | STS201 |

|---|---|---|---|---|

| Elong(10%) | Above 40 | 30MIN | Above 22 | 50-60 |

| Hardness | ≤200HV | ≤200HV | Below 200 | HRB100,HV 230 |

| Cr(%) | 18-20 | 16-18 | 16-18 | 16-18 |

| Ni(%) | 8-10 | 10-14 | ≤0.60% | 0.5-1.5 |

| C(%) | ≤0.08 | ≤0.07 | ≤0.12% | – |

The Manufacturing Process of Water Ripple Stainless Steel Sheets

In terms of the production process, commonly stainless steel surface treatment processes include wire drawing, mirror surface, sandblasting, titanium plating, etching, fingerprint resistance, etc.

The water ripple stainless steel sheets are made by stamping the pattern on the stainless steel plate by stamping.

When embossing is rolled, patterned work rolls are used, and the work rolls are usually processed with corrosive liquid. The depth of the bumps on the board varies with the pattern, about 20-30 microns.

The patterns and colors of the water wave-stamped stainless steel sheets can also be customized.

In the production process, the main body and the colored layer are integrated to maintain the basic structure and basic performance of the original stainless steel.

Application of water wave stamped stainless steel sheets

Wave stamped stainless steel sheets have long been popular in the decoration industry and various products. Because stainless steel has the advantages of corrosion resistance, durability, safety, environmental protection, fire protection, processing and molding, and surface polishing, the pattern is stamped on the stainless steel plate by stamping to form a wave stamped stainless steel sheets, and its three-dimensional vision is immediately presented in front of you, Therefore, in many occasions, wave stamped stainless steel sheets are used to make ceilings in large areas.