In the world of stainless steel, surface finish plays a crucial role in both aesthetics and functionality. Two popular finishes that often confuse are brushed and satin finishes. While they may look similar at first glance, the subtle differences can impact performance, cost, and application. As a leading brushed vs satin finish stainless steel supplier, Huaxiao Metal is here to help you make an informed decision.

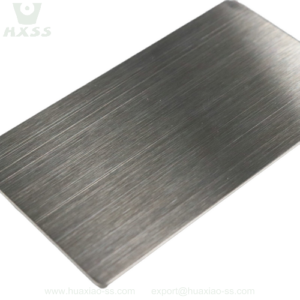

What is Brushed Finish Stainless Steel?

Brushed stainless steel is produced by polishing the surface with a fine abrasive belt to create a uniform, parallel grain pattern. The finish gives it a dull polish with a subtle texture.

Characteristics:

- Directional finish

- Low reflectivity

- Offers a modern, industrial look

- Scratches are visible but blend in with the grain

What is Satin Finish Stainless Steel?

Satin finish stainless steel is achieved through a soft, non-directional abrasive polishing process. The surface appears smooth and matte, with fewer visible lines than brushed finishes.

Characteristics:

- Uniform, low-gloss appearance

- Softer texture than a brushed finish

- More resistant to showing fingerprints and smudges

Brushed vs Satin Finish Stainless Steel: What’s the Difference?

When choosing between brushed and satin finish stainless steel, it’s important to understand their differences across several key dimensions. Below, Huaxiao Metal — your trusted brushed stainless steel supplier and satin finish stainless steel supplier — breaks down these differences in detail:

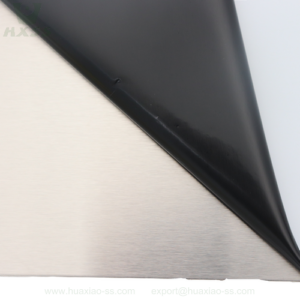

Texture and Appearance

- Brushed Finish:

Characterized by a linear, directional grain produced by sanding with fine abrasives. The lines are visible to the eye and create a rugged, industrial look.

Satin Finish:

Offers a smoother, softer surface with minimal visible grain. It appears more uniform and less textured, giving a clean and subtle appearance.

Durability and Maintenance

Brushed Stainless Steel:

Durable but can show fingerprints and oil stains easily. Scratches blend with the grain but may accumulate over time.

Satin Stainless Steel:

More resistant to smudges and everyday wear. Easier to maintain for high-contact applications like door handles or medical tools.

Reflectivity

Brushed Finish:

Low to moderate reflectivity due to directional lines that scatter light unevenly.

Satin Finish:

Uniform matte surface reflects light softly and evenly, offering a subdued, elegant look.

Applications

Brushed Stainless Steel:

Commonly used in kitchen appliances, architectural panels, automotive parts, and elevator doors.

Satin Stainless Steel:

Ideal for interior design elements, medical equipment, railings, sinks, and public utilities.

Huaxiao Metal supplies both finishes tailored to industrial and decorative uses — consult us now for custom solutions.

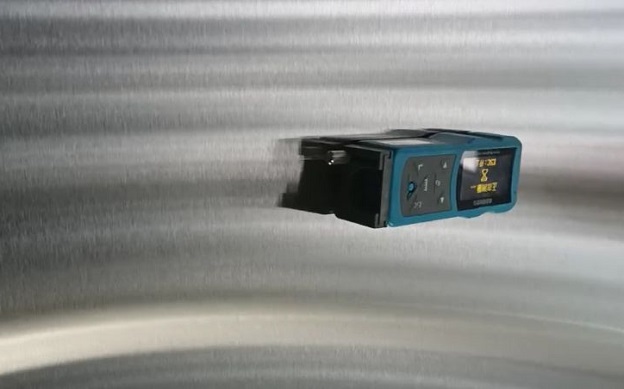

Manufacturing Process and Techniques

Brushed Finish:

Achieved by mechanically polishing the stainless steel surface with abrasive belts in a single direction.

Satin Finish:

Created using non-directional fine abrasives or scotch-brite pads, resulting in a smoother, matte finish.

Each method requires different machinery and controls — a key factor in supplier capability.

The Aesthetics Comparison

Brushed:

Sharp, bold, and modern. Often preferred for commercial kitchens, electronics, and high-tech environments.

Satin:

Sleek, soft, and neutral. Popular for minimalist and contemporary interior projects

Cost Considerations

Brushed Stainless Steel:

Slightly higher cost due to additional processing time and precision sanding.

Satin Stainless Steel:

Generally more cost-effective for large-scale applications requiring lower visual grain detail.

Huaxiao Metal provides competitive prices for both brushed and satin finish stainless steel in bulk — request your quote today.

Sustainability and Environmental Impact

Both finishes use recyclable stainless steel and eco-friendly processing when handled by responsible manufacturers like Huaxiao Metal. However:

Satin Finish:

Often requires fewer processing steps, reducing energy consumption.

Brushed Finish:

May consume more abrasives and energy during surface preparation.

We are committed to sustainable production practices. Ask us about green procurement.

Scratch Visibility

Brushed Finish:

Scratches are visible but blend with the existing grain, making them less prominent over time.

Satin Finish:

Scratches may stand out more on smooth surfaces but are often less noticeable due to the overall matte look.

Important consideration for high-traffic environments such as public transport or commercial kitchens.

How to Choose Between Brushed and Satin Finish Stainless Steel

When selecting a finish, consider the following factors:

Functionality:

For high-contact surfaces, satin finish is more practical due to its fingerprint resistance.

Aesthetics:

If you’re looking for a bold, industrial appearance, brushed finish may be more suitable.

Maintenance Requirements:

Satin finish is often easier to clean and maintain in high-traffic areas.

Budget:

Brushed finish is slightly more labor-intensive and may incur higher production costs.

Tip from Huaxiao Metal:

As professional brushed stainless steel suppliers and satin stainless steel suppliers, we recommend evaluating the end-use environment and maintenance expectations before choosing your surface finish.

Conclusion: Get the Right Finish from a Trusted Supplier

At Huaxiao Metal, we offer a wide range of stainless steel products with both brushed and satin finishes, available in various grades and dimensions. Whether you’re an architect, equipment manufacturer, or industrial contractor, we can provide custom surface finishes to meet your exact needs.

Contact Huaxiao Metal today to discuss your project requirements or request a free quote.

Explore our selection of brushed and satin finish stainless steel now!