Maintenance of Stainless Steel Handle

(1) The installation time of the stainless steel handle should be carried out after the room has been decorated and the site has been cleaned, so as to prevent bumps and bumps during the construction process or when cleaning the site, or the cleaning staff should be cleaned with acid-alkaline detergents handle. (2) The surface of […]

What are the design requirements for stainless steel staircase handrails in public places

What are the design requirements for stainless steel staircase handrails in public places? stainless steel staircase handrails are support bars for stair guardrails. They are used to support people when going up and down the stairs. They are used to support and assist pedestrians and play a role in relieving fatigue and safety. In the […]

How to maintain the stainless steel doors?

Buying stainless steel doors of reliable quality can make people feel more at ease, but if you want to extend the service life of the anti-theft door and make it last longer, you must do a good job of daily maintenance. And to do a good job in the daily maintenance of anti-theft doors, you […]

The features and application research of ferritic stainless steel

Research on Characteristics and Application of Ferritic Stainless Steel 1 Atmospheric corrosion resistance Since ferritic stainless steel has good atmospheric corrosion resistance, it has been used recently as the roof and curtain wall of buildings. However, the atmospheric environment in areas close to the sea is particularly harsh, especially the suspended particles from seawater and air are […]

What are the seven elements of operation and maintenance of stainless steel submersible pumps?

1. Stainless steel submersible pumps should be checked at regular intervals (about 1000h). The insulation resistance of the submersible pump should be checked before use. It should be no less than 0.5MΩ. If it does not meet the requirements, it should be dried. 2. Before use, check the cables, switches, and electric shock protectors, etc. […]

Super duplex stainless steel

The development of duplex stainless steel has gone through 3 generations: the first generation is represented by the 3RE60 steel in the mid-1960s, which has the problem of welding heat affected zone; the second generation is after the 1970s, the development of ultra-low carbon and Nitrogen-containing characteristics, the representative grade is 2205, and the pitting equivalent index […]

Rolling force calculation and parameter influence analysis of wide and thick stainless clad plate

Stainless clad plate is a metallurgical combination of base material (carbon steel or low alloy steel) and cladding material (stainless steel) through high-temperature heating and pressure deformation, making it an integral laminated material with special properties. Based on corrosion resistance considerations, wide and thick stainless steel composite panels have broad application prospects in high-end industries […]

Stainless Steel Grades

Stainless steel grades 200 – chrome – nickel – manganese series, 300 series – chrome – nickel, 301, 302, 303, 304, 309, 316, 321, 400 series – ferritic and martensitic stainless steel, 408, 409, 410, 416, 420, 430, 440, 500 series – heat resistant chromium alloy steel, 600 series – martensitic precipitation hardening stainless steel. […]

The maintenance of the stainless steel staircase column

The importance of maintenance of stainless steel staircase columns Stainless steel staircase columns are generally used in homes, shopping malls, and various public places in office buildings. In daily work, many people neglect the maintenance of stainless steel stair columns. Stainless steel stair columns are generally made of stainless steel, but many people think that […]

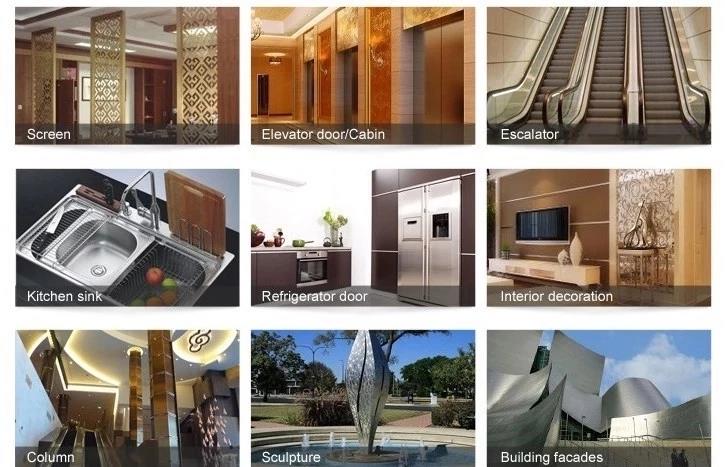

Application places and maintenance methods of decorative stainless steel pipes

As one of the most commonly used pipe materials, decorative stainless steel pipe has a wide range of applications and has penetrated almost all aspects of our life and production. Today, I will talk to you about the specific application areas and maintenance methods of decorative stainless steel pipes. Stainless steel decorative pipe is actually a […]